- Accueil

- Informations

- Produits

- MAGASIN

- Marchés

- Applications

- Support

- Contact

- Nouvelles

Types de Capteurs de Pesage

Capteurs de Pesage sont l'épine dorsale de la mesure de précision dans diverses industries, offrant des solutions variées pour mesurer la force, le poids et la pression. Il est essentiel de comprendre les différents types de Capteurs de Pesage pour sélectionner la solution optimale qui répondra aux exigences spécifiques de votre application. Dans cette section, nous explorerons en détail la technologie des jauges de contrainte ainsi que trois types courants de Capteurs de Pesage : compression Capteurs de Pesage, tension Capteurs de Pesage et poutre Capteurs de Pesage.

Jauge de contrainte Capteurs de Pesage:

Les jauges de contrainte Capteurs de Pesage représentent la pierre angulaire de la technologie moderne de mesure de la force, offrant une précision, une fiabilité et une polyvalence inégalées. Ces Capteurs de Pesage fonctionnent sur le principe de la variation de la résistance électrique dans les jauges de contrainte collées à un élément métallique, généralement disposé dans une configuration de pont de Wheatstone. Pour en savoir plus sur les différences entre les charges et les jauges de contrainte , cliquez ici.

Principe de fonctionnement :

Les jauges de contrainte Capteurs de Pesage reposent sur l'effet piézorésistif, où des changements de résistance se produisent en réponse à une déformation mécanique. Lorsqu'une force est appliquée au site Capteurs de Pesage, l'élément métallique subit une déformation, ce qui entraîne l'allongement ou la contraction des jauges de contrainte. Ce changement de longueur modifie la résistance des jauges de contrainte, ce qui entraîne un changement mesurable de la sortie électrique. En mesurant précisément ce changement de résistance, les jauges de contrainte Capteurs de Pesage déterminent avec précision la force appliquée.

Construction et conception :

Les jauges de contrainte Capteurs de Pesage sont généralement fabriquées à partir de matériaux de haute qualité, tels que l'acier inoxydable ou l'aluminium, afin de garantir leur durabilité et leur stabilité. Les jauges de contrainte sont soigneusement collées à l'élément métallique, avec un alignement précis pour maximiser la sensibilité et la précision. Certains Capteurs de Pesage sont dotés de protections supplémentaires, telles que des connecteurs et des câbles spéciaux, afin de les protéger contre les facteurs environnementaux tels que l'humidité, l'eau et les atmosphères explosives.

Jauge de contrainte Capteurs de Pesage Conclusion :

Les jauges de contrainte Capteurs de Pesage sont les piliers de la mesure de précision, offrant une précision, une fiabilité et une adaptabilité inégalées dans une myriade d'applications. Avec leur construction robuste, leur sensibilité élevée et leur large gamme de capacités, les jauges de contrainte Capteurs de Pesage continuent de stimuler l'innovation et l'excellence dans des secteurs allant de la fabrication et de l'ingénierie à la recherche et au développement.

Pour en savoir plus sur les jauges de contrainte, cliquez ici.

Compression Capteurs de Pesage:

Un appareil de compression Capteurs de Pesage est l'un des principaux types d'appareils de mesure Capteurs de Pesage et, comme son nom l'indique, il mesure les forces descendantes ou de poussée. Ils sont généralement placés sous l'objet à mesurer ou à peser ou, dans le cas de Axes Dynamométriques, remplacent un axe porteur existant qui se trouve directement sur le trajet de la charge.

Leurs utilisations sont très diverses, allant du pesage de grandes capacités, comme les silos et les grandes structures offshore, au pesage de grues et de treuils et à la surveillance des surcharges.

Voyons plus en détail les principales caractéristiques, les avantages et les applications de la compression Capteurs de Pesage:

Principe de fonctionnement :

Construction et conception :

Un exemple typique de compression Capteurs de Pesage est la colonne Capteurs de Pesage. Il s'agit de dispositifs de forme cylindrique avec une surface plane en haut et en bas. À l'intérieur, il y a un noyau central ou une colonne qui sert d'élément porteur. Des jauges de contrainte sont collées à la surface de cette colonne, orientées de manière à détecter les déformations qui se produisent sous la charge. Le site Capteurs de Pesage est doté d'un couvercle extérieur destiné à protéger les jauges de contrainte et les conditions environnementales externes. Ces Capteurs de Pesage sont robustes et fournissent des mesures de charge très précises.

Parmi les autres modèles courants de compression Capteurs de Pesage , on peut citer le pancake ou le bouton Capteurs de Pesage, qui sont compacts et discrets, et sont utilisés lorsque l'espace est limité. Le beignet ou la rondelle Capteurs de Pesage sont dotés d'un trou central permettant le passage de mécanismes ou de composants.

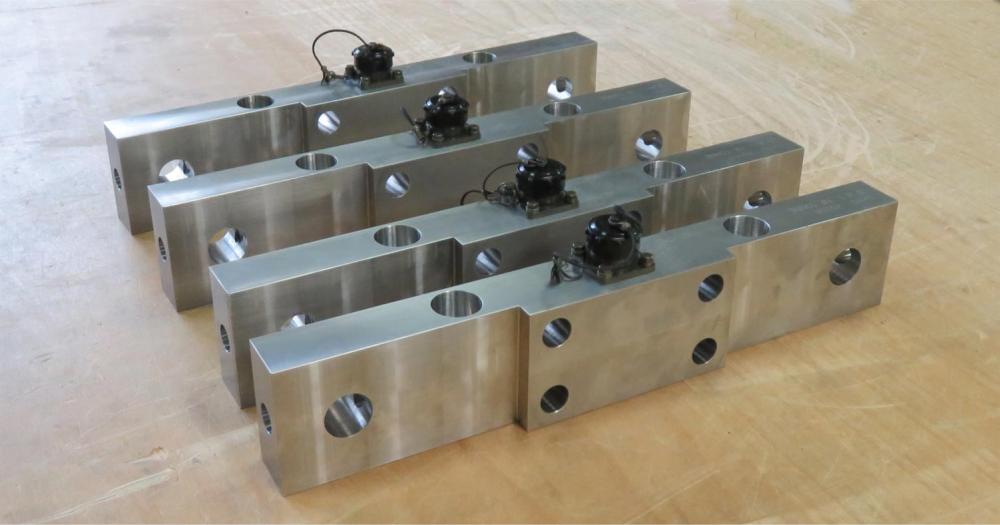

Un autre type de dispositif de mesure de la charge de compression est le Axes Dynamométriques, qui a été conçu pour de nombreuses applications diverses en remplacement direct des goupilles porteuses. Ils présentent de nombreux avantages par rapport aux autres capteurs de charge, car ils ne nécessitent normalement aucune modification de la structure dans laquelle ils sont installés. Axes Dynamométriques est généralement utilisé dans les ancrages de câbles, de chaînes et de freins, les poulies, les blocs de roulements et les pivots. Le Axes Dynamométriques possède un alésage central autour duquel les jauges de contrainte sont positionnées. Contrairement à la colonne Capteurs de Pesage, cela signifie qu'ils n'ont pas besoin d'un couvercle de protection, car les jauges de contrainte sont entièrement scellées à l'intérieur du Axes Dynamométriques. Cependant, comme ils sont souvent soumis à des restrictions dimensionnelles, ils offrent généralement des précisions inférieures à celles d'autres types de compression Capteurs de Pesage.

Compression Capteurs de Pesage Conclusion :

Les appareils de compression Capteurs de Pesage sont les piliers de la mesure de force à usage intensif, offrant une capacité, une stabilité et une fiabilité inégalées dans les environnements industriels exigeants. Grâce à leur construction robuste et à leurs options de haute précision, les appareils de compression Capteurs de Pesage continuent de jouer un rôle essentiel pour garantir la sécurité, l'efficacité et la qualité dans un large éventail d'applications dans de nombreuses industries différentes.

Tension Capteurs de Pesage:

Les appareils pneumatiques Capteurs de Pesage sont des dispositifs innovants de mesure de la force qui fonctionnent sur le principe des variations de pression de l'air pour mesurer la force avec précision. Réputés pour leur sensibilité, leur fiabilité et leur immunité aux interférences électromagnétiques, les appareils pneumatiques Capteurs de Pesage trouvent des applications dans des environnements où la précision de la mesure de la force est essentielle. Voyons plus en détail les principales caractéristiques des appareils pneumatiques Capteurs de Pesage:

Principe de fonctionnement :

Le site Capteurs de Pesage utilise le principe de la variation de la pression de l'air pour mesurer la force. Ils sont constitués d'un diaphragme ou d'un soufflet qui se déforme sous l'effet de la charge, provoquant une variation de la pression de l'air dans un système fermé. Ce changement de pression est proportionnel à la force appliquée et est mesuré et converti en un signal électrique, fournissant une indication précise de la force appliquée.

Construction et conception :

Le site Capteurs de Pesage est généralement construit dans des matériaux tels que l'acier inoxydable ou l'aluminium, afin de garantir sa durabilité et sa stabilité. Le boîtier Capteurs de Pesage contient une membrane ou un soufflet qui se déforme sous l'effet de la charge, ainsi que des capteurs ou des transducteurs qui mesurent les variations de pression qui en résultent. Le système pneumatique est soigneusement conçu pour minimiser les frottements, les fuites et les effets de la température afin de garantir des performances précises et fiables.

Tension Capteurs de Pesage Conclusion :

Les appareils pneumatiques Capteurs de Pesage offrent des capacités de mesure de précision dans des environnements contrôlés, avec une sensibilité élevée, une grande fiabilité et une immunité aux interférences électromagnétiques. Grâce à leur construction robuste, à leur large plage de températures de fonctionnement et à leur compatibilité avec les salles blanches, les appareils pneumatiques Capteurs de Pesage continuent de jouer un rôle essentiel en garantissant la précision et la qualité dans un grand nombre d'applications industrielles.

Cisaillement Capteurs de Pesage:

Les appareils hydrauliques Capteurs de Pesage sont des dispositifs robustes de mesure de la force qui utilisent un fluide hydraulique et des pistons pour mesurer la force avec précision. Réputés pour leur durabilité, leur stabilité et leur grande capacité, les appareils hydrauliques Capteurs de Pesage excellent dans les environnements industriels exigeants où la précision et la fiabilité sont primordiales. Voyons plus en détail les principales caractéristiques, les avantages et les applications des appareils hydrauliques Capteurs de Pesage:

Principe de fonctionnement :

Les pompes hydrauliques Capteurs de Pesage fonctionnent selon la loi de Pascal, qui stipule que la pression exercée sur un fluide confiné est transmise sans diminution dans toutes les directions. Lorsqu'une force est appliquée au Capteurs de Pesage, elle comprime le fluide hydraulique à l'intérieur d'une chambre étanche, provoquant un déplacement proportionnel du piston ou du diaphragme. Ce déplacement est mesuré et converti en un signal électrique, fournissant une indication précise de la force appliquée.

Construction et conception :

Le système hydraulique Capteurs de Pesage est généralement construit avec des matériaux très résistants, tels que l'acier inoxydable ou l'acier allié, afin de supporter des charges lourdes et des conditions de fonctionnement difficiles. Le boîtier Capteurs de Pesage contient un piston ou un diaphragme qui comprime le fluide hydraulique, ainsi que des jauges de contrainte ou d'autres éléments de détection pour mesurer le déplacement. Le fluide hydraulique est soigneusement sélectionné en fonction de sa stabilité, de sa viscosité et de ses caractéristiques de température afin de garantir des performances précises et fiables.

Poutre Capteurs de Pesage Conclusion :

Les appareils hydrauliques Capteurs de Pesage sont les piliers de la mesure de force à usage intensif, offrant une capacité, une stabilité et une fiabilité inégalées dans les environnements industriels exigeants. Grâce à leur construction robuste, leur haute précision et leur immunité aux interférences électromagnétiques, les capteurs hydrauliques Capteurs de Pesage continuent de jouer un rôle essentiel pour garantir la sécurité, l'efficacité et la qualité dans une large gamme d'applications industrielles.

Résumé

En résumé, cette section a exploré trois types fondamentaux de Capteurs de Pesage- compression, tension et faisceau - en mettant l'accent sur leurs principes de fonctionnement distinctifs et leurs caractéristiques de construction. Les jauges de contrainte Capteurs de Pesage, connues pour leur précision et leur polyvalence, représentent la pierre angulaire de la mesure moderne de la force, offrant une précision et une fiabilité inégalées dans divers secteurs industriels. Comprendre les nuances de ces types Capteurs de Pesage permet aux industries de faire des choix éclairés, d'optimiser les processus et de garantir des performances, une efficacité et des normes de sécurité de premier ordre.