LCM4643-ATEX 12te Manilles Dynamométriques avec affichage ATEX et système d'alarme

Il s'agissait d'un entrepreneur international de forage en mer qui fournit des services pétroliers pour la production de pétrole et de gaz en mer, spécialisé dans le secteur des eaux très profondes. L'entreprise avait besoin d'un site Manilles Dynamométriques classé ATEX Zone 2, avec des écrans et des alarmes, pour l'un de ses navires de forage en eaux profondes déployé au large de l'Angola dans le cadre du projet Kaombo en eaux très profondes. En raison des règles strictes de leurs clients concernant les zones dangereuses, ils avaient besoin de produits certifiés pour se conformer à ces règles.

LCM Systems a conçu un système répondant à leurs exigences, comprenant 3 x 12 tonnes Manilles Dynamométriques et une boîte de jonction ATEX située au sommet d'un cadre en A, câblée à une autre boîte de jonction ATEX à sa base et connectée à un système d'affichage et d'alarme ATEX à 3 canaux (voir la photo ci-dessous). Un autre système d'affichage et d'alarme, situé sous le pont dans la cabine du foreur, était également connecté à cette boîte de jonction. Comme il était situé dans la zone de sécurité, il n'était pas nécessaire qu'il soit certifié ATEX. En raison de l'environnement de travail difficile, tous les câbles fournis étaient des câbles d'alimentation/instrumentation blindés RFOU (I) 250V résistants à la boue, spécialement conçus pour les systèmes critiques de sécurité dans les zones EX et sûres.

Le site Manilles Dynamométriques devait surveiller les charges sur les poulies des rouleaux ombilicaux pendant qu'ils déroulaient le tuyau pour s'assurer qu'il ne s'affaissait pas et pour vérifier que les enrouleurs de tuyaux hydrauliques fonctionnaient correctement. Chaque site Manilles Dynamométriques disposait de son propre écran pour afficher les charges individuelles, et tous trois étaient réglés pour déclencher une alarme sonore et visuelle en cas d'atteinte d'une limite prédéfinie. Un second système d'affichage et d'alarme a été incorporé dans la cabine de forage pour la surveillance à distance du système.

Nous avons ensuite reçu une commande identique pour le même système pour un autre opérateur de navire de forage en eaux profondes travaillant sur le même projet.

Les principaux critères qui nous ont été communiqués sont les suivants :

- Manilles Dynamométriques et les systèmes d'affichage et d'alarme doivent être certifiés pour une utilisation dans les zones dangereuses de la zone 2.

- Niveaux de déclenchement spécifiés par le client pour chaque Manilles Dynamométriques à définir

- Systèmes d'alarme double intégrés pour le pont supérieur et le pont inférieur requis

- Le système doit pouvoir être utilisé dans un environnement offshore.

- Traçabilité complète des matériaux requise

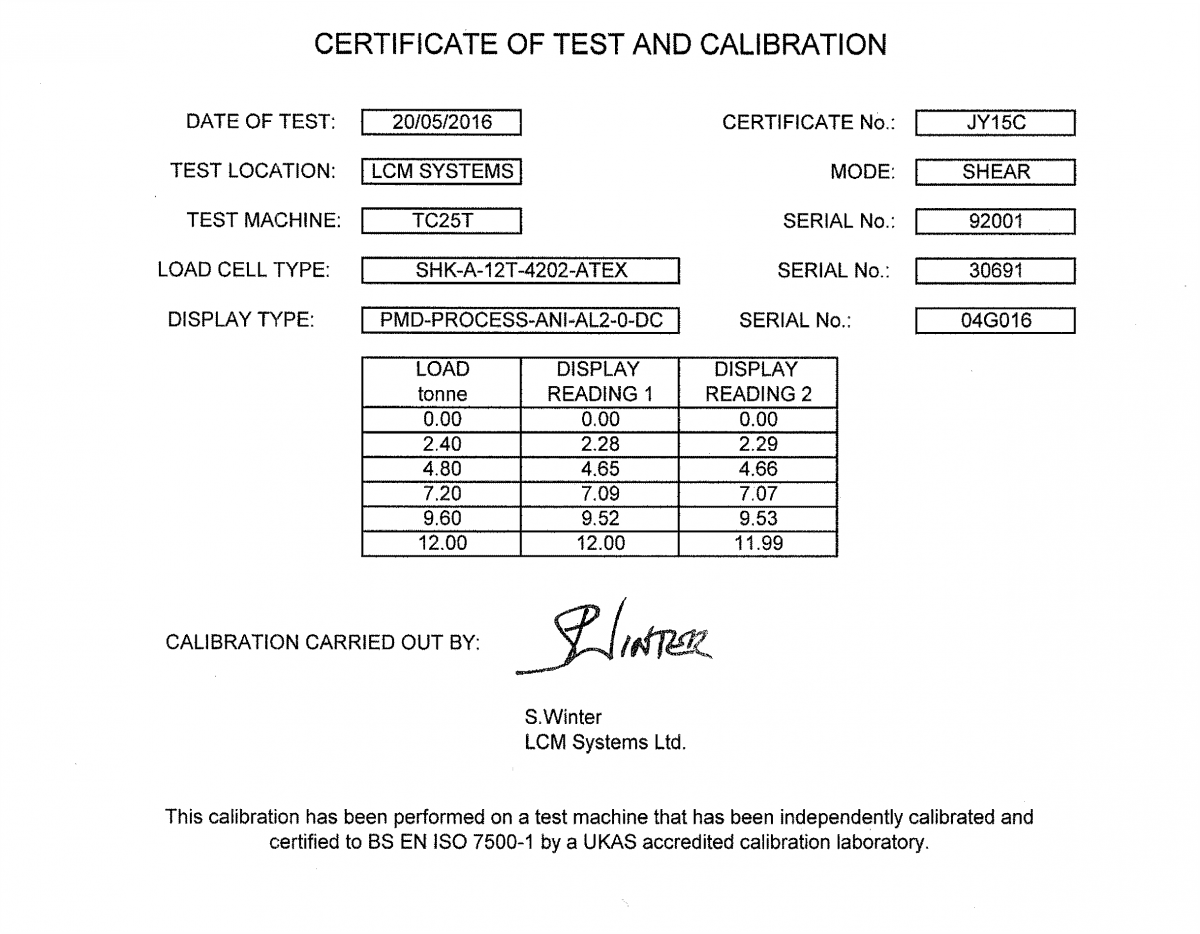

- Les manilles de charge doivent être étalonnées selon des normes traçables.

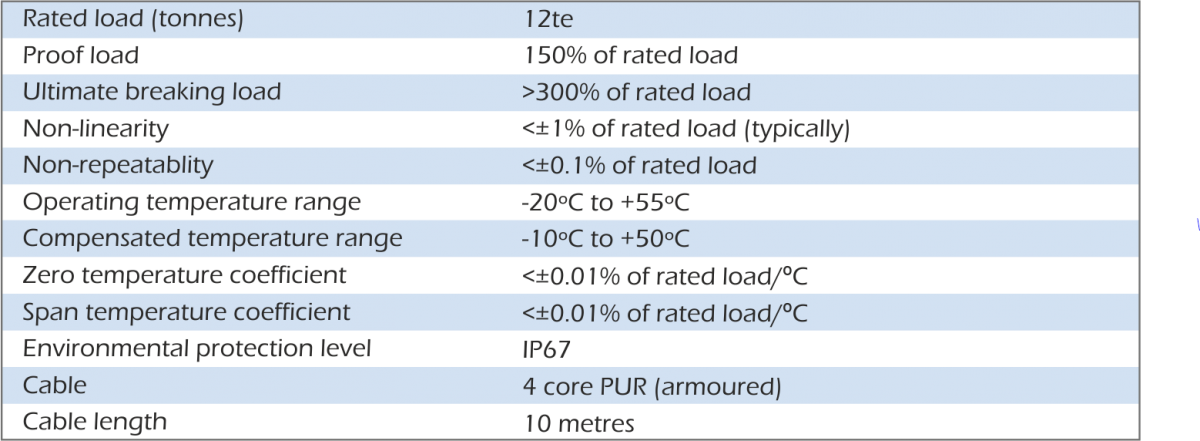

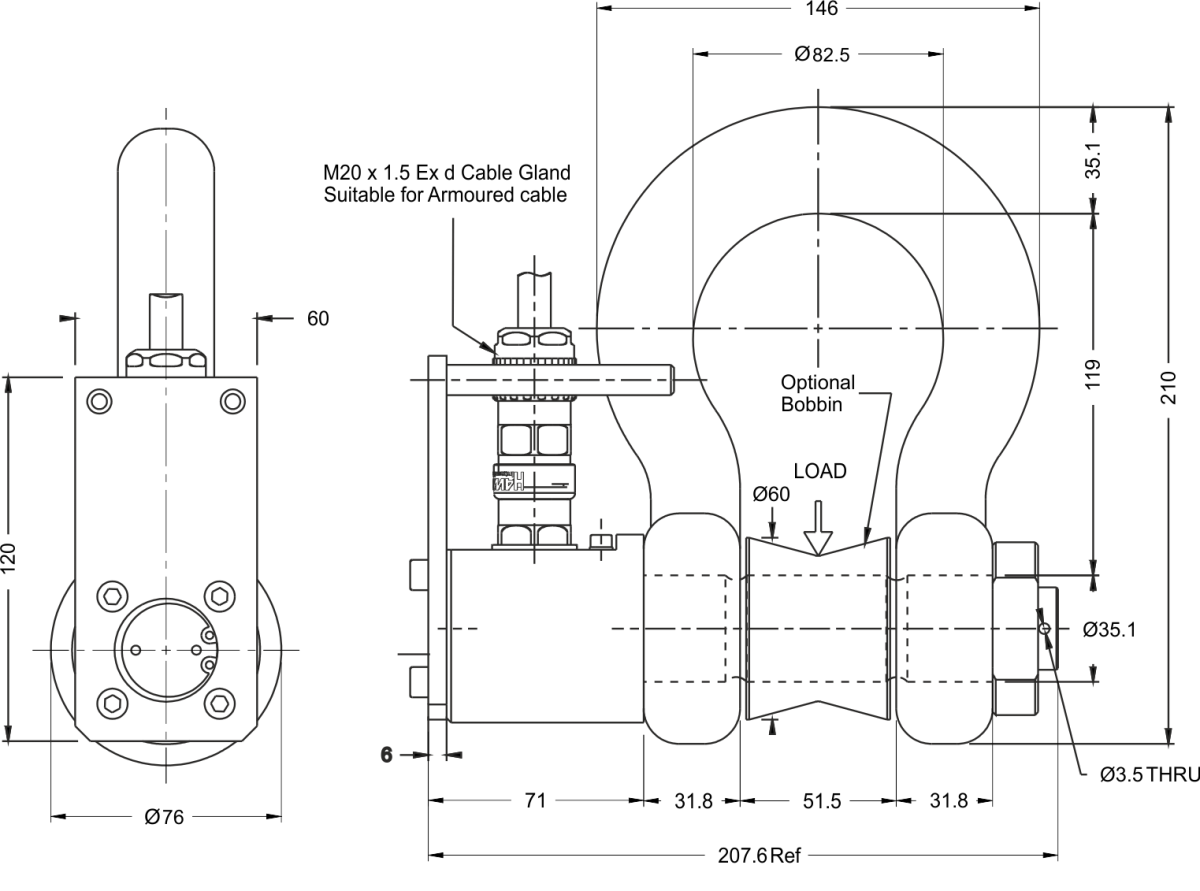

- 12te ATEX Manilles Dynamométriques

- Boîte de jonction de terminaison à 3 canaux en aluminium certifiée ATEX Capteurs de Pesage

- Boîte de terminaison et de jonction à 3 canaux en aluminium certifiée ATEX

- Alarmes sonores et visuelles

- Étanchéité à l'environnement selon IP67

- Axes Dynamométriques fabriqué en acier inoxydable 17-4PH H1150

- Fabriqué à l'aide d'une manille Crosby G2130

- Fourni avec un écran certifié ATEX

- Fourni avec une bobine de chargement pour une précision optimale

- Fourni avec l'écran PMD-PROCESS pour la zone de sécurité