LCM3064 150te Sub-Sea Submersible Type D Manilles Dynamométriques

Cette demande de produit émane d'un de nos clients réguliers, un intégrateur de systèmes d'ingénierie offshore basé au Royaume-Uni. En général, nous leur fournissons Axes Dynamométriques, qui est installé dans des assemblages de manilles et de liens qui existent déjà sur le site. Cette fois-ci, ils avaient besoin d'une solution complète, avec une traçabilité totale tout au long du processus de fabrication.

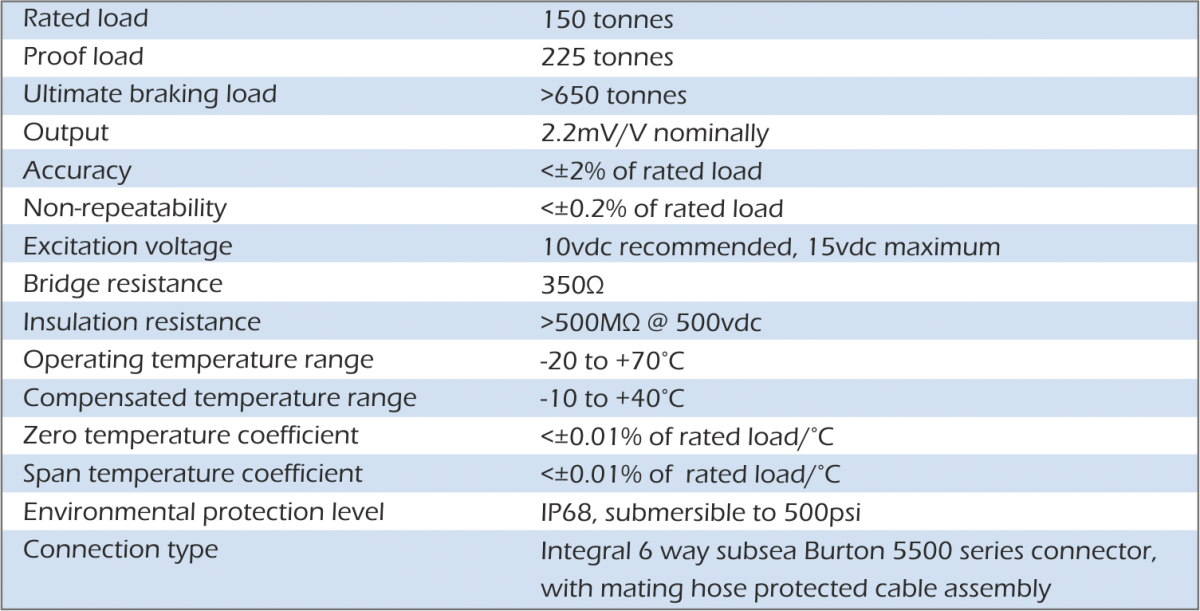

Le site Capteurs de Pesage devait avoir une capacité de 150te et devait être utilisé pour mesurer la tension des amarres. La conception devait résister à une immersion totale dans l'eau de mer. Des certificats de matériaux et de charge d'épreuve ont été exigés pour la manille. La goupille de la manille devait être fabriquée en acier inoxydable. La goupille devait faire l'objet d'une traçabilité complète, la charge d'épreuve finale, l'étalonnage et la documentation devant être inspectés et attestés par l'ABS (American Bureau of Shipping).

Les principaux critères qui nous ont été communiqués sont les suivants :

- Le site Capteurs de Pesage devait être un modèle de manille Capteurs de Pesage et devait s'adapter à une plaque de liaison existante, déjà sur le site.

- Le site Axes Dynamométriques devait être fabriqué en acier inoxydable 17-4PH.

- Des certificats de matériaux ont été exigés pour toutes les pièces critiques supportant des charges.

- Le produit final devait résister à une immersion totale à 500 psi.

- Pour des raisons d'assurance du site, une inspection par un témoin de l'ABS a été exigée.

- Tous les câbles devaient être robustes et protégés

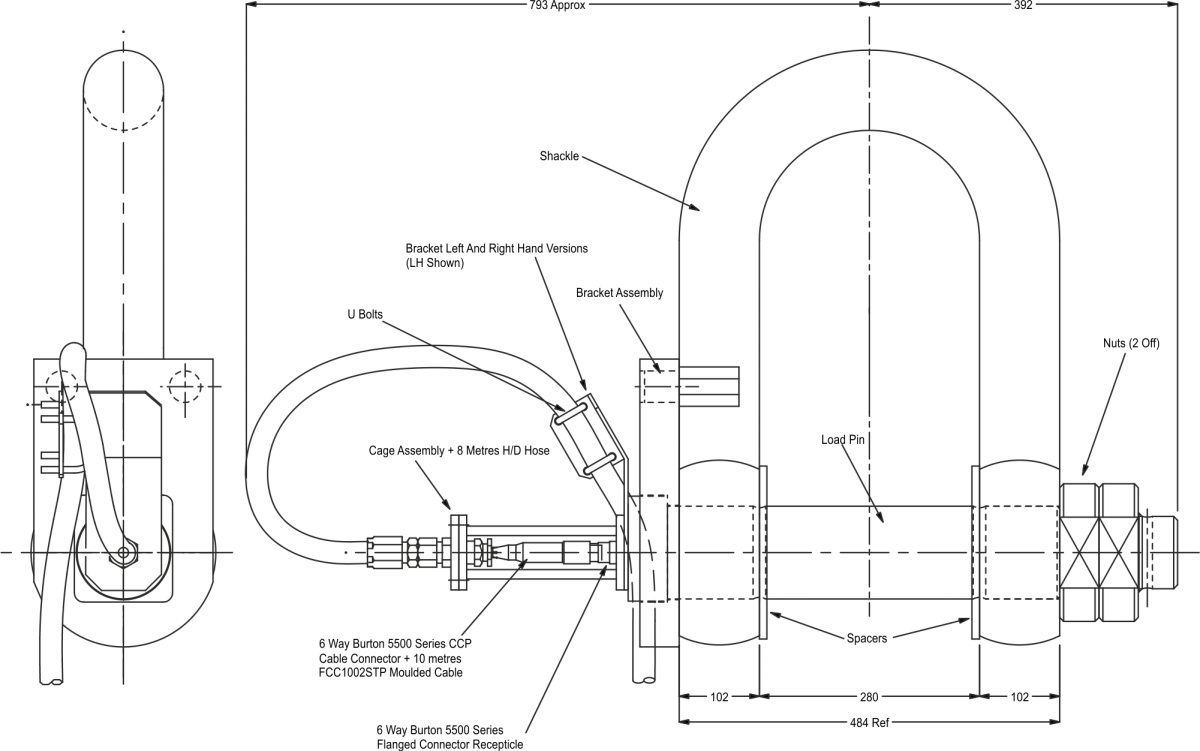

- 150te Subsea Manilles Dynamométriques

- Un connecteur sous-marin intégré de la série Burton 5500 a été utilisé.

- Traçabilité complète, avec inspection par un témoin ABS de la documentation, de la charge d'épreuve et de l'étalonnage final

- Manille GN Rope H11

- Des entretoises libres sont fournies pour permettre une certaine flexibilité lors de l'installation dans une plaque de liaison à tolérances larges.

- Assemblage d'un câble de connexion sous-marin moulé de 10 m, protégé par un tuyau hydraulique renforcé en acier pour usage intensif

- L'axe de la manille est fabriqué en acier inoxydable 17-4PH.

- Support spécial anti-rotation